Categories

- Balance (11)

- Book (5)

- Chromatography (21)

- Clinical Trial (14)

- Engineering (48)

- FDA (4)

- Formulation Development (31)

- HPLC (20)

- Human Resource (12)

- Microbiology (50)

- Packing (26)

- Parenteral (5)

- Pharmacist (55)

- Pharmacoeconomics (43)

- Production (103)

- Qualification (4)

- Quality Assurance (77)

- Quality Control (199)

- Regulatory Affair (41)

- Validation (19)

- Warehouse (42)

.webp)

Medical Devices Regulation for United Arab Emirates (UAE)

October 06, 2024

SOP for Receipt of Raw and Packing Material

December 06, 2023

SOP for Storage of Approved Packaging Materials

December 05, 2023

SOP for Numbering System of Analytical Report Number

November 16, 2023

SOP for Calibration of Shimadzu UV–1800 UV Spectrophotometer

November 23, 2023

Containers and Closures

June 15, 2023

How to Set In-Vitro Dissolution Test Apparatus?

June 15, 2023

SOP for Calibration of Hot Plate Stirrer

March 06, 2025

SOP for Operation and Calibration of Gas Chromatography (CHEMITO-7610 ECD)

PharmaInfo

December 13, 2023

Objective

The objective of this SOP is to lay down the procedure for the operation and calibration of Gas chromatography.

Scope

This SOP covers the operation and calibration procedure of Gas chromatography.

Responsibility

QC Officer: Responsible for the operation and maintenance of the instrument as per the procedure.

Head of Department: Responsible for maintenance, timely as per schedule.

QA Officer/QA Manager: Review the records and documents.

Procedure

OPERATION

- Ensure that the instrument is visibly clean and free from dust. Wipe all the traces of solvent/water/moisture with a dry cloth.

- Install a properly suitable capillary column in the GC oven injector & selected detector.

- Open the Gas pressure valve from the distribution panel. Check the back pressure of the column.

- Switch on the mains of the instrument & computer.

- Set the column flow as per requirement from the upper panel by a dial gauge.

ALSO READ: SOP for Shimadzu LabSolutions

- Press the oven key on the front panel of the instrument and set the oven temperature.

- Then press the temperatures key for the injector and detector temperature and set the required temperature for the same.

Software Operation:

- Double Click on C2001 1.7 Icon. Chemitochrom-2000 window display on the screen.

- Select and click the login menu, Select GC 1 or GC 2 as per requirement, and click. Add analyst name or Password. My GC (Work 1 or 2) window display.

- Select the file and click on New or Open (for New file or open file), Select File Type display, and Select any one ‘Sequence’, ‘Instrument’, ‘Method’, ‘Project’ etc.

- Click on the ‘Method’ button, add the file name, and click on OK. Now select the file menu and click on open, ‘Open Method File’ window display. Select the required file name and click on OK.

- Now select and click on setting, select method and click, or click on chromatogram with scale icon, method window display on the screen Feed require parameters Noise, threshold, etc. and click on OK.

- Select and click on setting, select Instrument and click, or click on the column icon, The Instrument window displays on the screen. Feed requires parameters column, mobile phase, Flow rate, pressure, detection, temperature, etc., and click on OK.

- Now select and click on setting, select Analysis and click, or click on the injection icon, analysis window displays on the screen. Feed requires parameters Sample ID, File Name, etc., and click on OK.

- Select and choose the Chromatogram icon Blue or Red (=>). If choose blue (=>) auto opens the new graph (Running graph) after injection and if choose red (=>) opens the previous graph after injection. ( Always choose Red (=>).

- Select Chromatogram with peak report icon Blue or Red (=>). If choose blue (=>) auto print out (Running graph) after the completed run and if choose red (=>) no print out after the completed run. Always choose Red (=>).

- Select and click Chromatogram with peak report icon and click on the OK button for printout.

- Now that all parameters and the instrument are ready for injection, inject the solution and immediately click on the ‘RUN’ Button.

- Select the method icon, chromatogram window displays on the screen, select the calculation parameter, open the file name, select the required file,, and click on OK, then again click OK on the chromatogram display with calibration parameters, then click on the printer icon and print the chromatogram.

Preparation of new print format:

- Click on the printer icon click on the New button, add the file name, and click OK. Now click on the setup button, style set up window 1 or 2 display on the screen.

- Select and click on Labor Header, add no of lines 3, Select line 1st, and add on select line.

- Select on 1st Page and border and click OK. Choose Report Header, choose Chromatogram choose portrait and as on screen, then click on OK.

- Select Result and click, choose result table, column performance, and click OK. Then again click OK.

ALSO READ: GC Troubleshooting Tips

- After completion of the analysis enter the details in the instrument usage log book as given in Annexure – 1.

- After completion of the injection, down the column temp below 35° C,, and the injector and detector temperature also cool down. Now close the gas flow and close the valve of a gas cylinder of Z- air, Hydrogen, and carrier gas ( Nitrogen or Helium).

CALIBRATION

- Open the column oven compartment.

- Install the proper capillary column.

- Connect the soap film flow meter to the detector port outlet with the help of Teflon or a rubber tube.

- Fill the pipette bulb partially with a soap solution and attach it to the bottom of the flow meter.

- Open the knob of carrier gas (N2) and set up proper pressure (i.e. 500 kph or 5 Kg/cm2) in the carrier gas pressure controller.

- Check for leaks at each and every point of attachment using soap solution.

- Open the knob of the carrier gas flow controller & allow carrier gas to flow through the corresponding digital flow control.

- Adjust the carrier gas flow rate with flow control (30 ml/min).

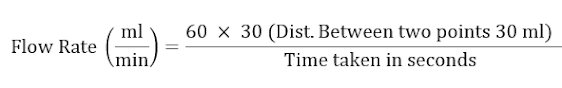

- Gentle squeeze the bulb to force a soap film up into the gas stream. Start the stopwatch as soon as the film reaches to zero ml mark. Stop the watch when the film reaches to 30 ml marking. Note down the time required to reach the film from 0 to 30 ml mark. Calculate the flow rate using the following formula.

- Similarly calibrate the flow rate after the time interval of 20 min, 40 min, & 60 min and find out the difference between the readings.

Detector precision and consistency of relative retention time:

Preparation of pesticide standard (0.2ppm):

- Take 100µl of standard solution (100ppm) of Gamma-BHC (Lindane) in a 10 ml volumetric flask containing 5 ml hexane and dilute to mark with the same solvent. Take 2 ml of this solution in a 10 ml volumetric flask and dilute to mark with hexane.

- Inject 2.0µl of pesticides standard 5 times and observe area and RT.

Acceptance criteria: The deviation for RT ± 0.2 min and deviation for area ± 10%

Detector Linearity:

- Prepare the five different concentration solution as follow to check the detector linearity.

- Take 100µl of standard solution (100ppm) of Gamma-BHC (Lindane) in a 10 ml volumetric flask containing 5 ml hexane and dilute to mark with the same solvent. Take 1 ml of this solution in a 10 ml volumetric flask and dilute to mark with hexane. Take 5ml of this solution in a 10ml volumetric flask and dilute to mark with hexane. Take a further 5ml in a 10ml volumetric flask and dilute to mark with hexane.

- Take 100µl of standard solution (100ppm) of Gamma-BHC (Lindane) in a 10 ml volumetric flask containing 5 ml hexane and dilute to mark with the same solvent. Take 1 ml of this solution in a 10ml volumetric flask and dilute to mark with hexane. Take a further 5ml in a 10ml volumetric flask and dilute to mark with hexane.

Preparation of pesticide standard 3 (0.1ppm):

- Take 100µl of standard solution (100ppm) of Gamma-BHC (Lindane) in a 10 ml volumetric flask containing 5 ml hexane and dilute to mark with the same solvent. Take 1 ml of this solution in a 10ml volumetric flask and dilute to mark with hexane.

Preparation of pesticide standard 4 (0.2ppm):

- Take 100µl of standard solution (100ppm) of Gamma-BHC (Lindane) in a 10 ml volumetric flask containing 5 ml hexane and dilute to mark with the same solvent. Take 1 ml of this solution in a 5 ml volumetric flask and dilute to mark with hexane.

Preparation of pesticide standard 5 (0.4ppm)

- Take 100 ml of the standard solution (100ppm) of gamma-BHC (lindane) in a 10 ml volumetric flask containing 5 ml hexane and dilute to mark with the same solvent. Take 2 ml of this solution in a 5 ml volumetric flask and dilute to mark with hexane.

- Inject 3 replicates the injection of the above solution and observes the area.

- Plot the graph of linearity and calculate the correlation coefficient.

CHROMATOGRAPHIC CONDITION:

Name of the instrument: GC [Chemito-7610]

Column : TR-5 [30m x 0.32 mm ID x 1.0µm]

Oven Temp. : 120°C (1min) @ 5°C/min 270°C (3 min)

Injector Temp. : 225°C

Detector Temp. : 300°C

Carrier Gas: N2 [1.2 bar]

Injection Volume: 2.0µl

Split Ratio: Split less

Acceptance criteria: The correlation coefficient shall be a minimum of 0.99

Calibration of Oven:

Calibration of oven to be done by calibration department

Frequency of calibration: Quarterly

Routine Maintenance

- Clean all the outside parts of the instrument.

- Clean the injector and injector liner. Change the glass wool and septa if required.

- Check all connections of gases for leakage.

Annexure

Annexure – 1 Gas chromatography system usage logbook.

Annexure –2 Gas chromatography calibration record

Annexure –3 Routine Maintenance Format

Revision History

Nil

Popular Posts

SOP for Handling of Deviation

October 14, 2023

Drug Approval Process in Europe

May 30, 2023

Drug Approval Process in Japan

June 29, 2023

New Drug Application (NDA) Process

June 06, 2023

SOP for System Suitability Test in HPLC analysis and HPLC Documentation

September 01, 2023

SOP for Preventive Maintenance of HPLC

September 03, 2023

Effective Dossier Management in Regulatory Affairs

June 26, 2023

Most Popular

SOP for Receipt, Storage and Dispatch of Finished Goods

December 06, 2023

Medical Devices Regulation for United Arab Emirates (UAE)

October 06, 2024

SOP for Receipt of Raw and Packing Material

December 06, 2023

Footer Menu Widget

Copyright © 2025 PharmaInfo All Right Reserved.

Created By Blogspot Theme | Distributed By Gooyaabi Templates

.webp)

0 Comments